Stainless Bars.

A WIDE RANGE FOR ALL VARIANTS.

ROUND BARS.

Stainless steel round bars (stainless bars) are most commonly used in mechanical engineering and for furniture.

They differ in 2 categories depending on the surface finish.

Cold Drawn stainless steel round bar are available in bars generally 3m long (but also 4m or 6m) or customised lengths.

The main characteristic is the diameter tolerance, more precise for cod drawn (ex: h9 tolerance). It is possible to order stainless steel round bars with h8 tolerances or even more precise like h7.

Chamfering each side of the bar allows better use on automatic loading machines.

Stainless steel hot rolled round bars are also sold in bars of varying lengths (from 4.5m to 6.5m) or cut to length.

The diameter tolerance is wider (e.g. k11) sometimes it is simply passed on a lathe to even out the surface (hence its commonly used name of peeled stainless steel round bar).

For all round bars, the stainless steel in which they are generally marketed is AISI 304, AISI 316, AISI 303 (containing sulphur) or AISI 420.

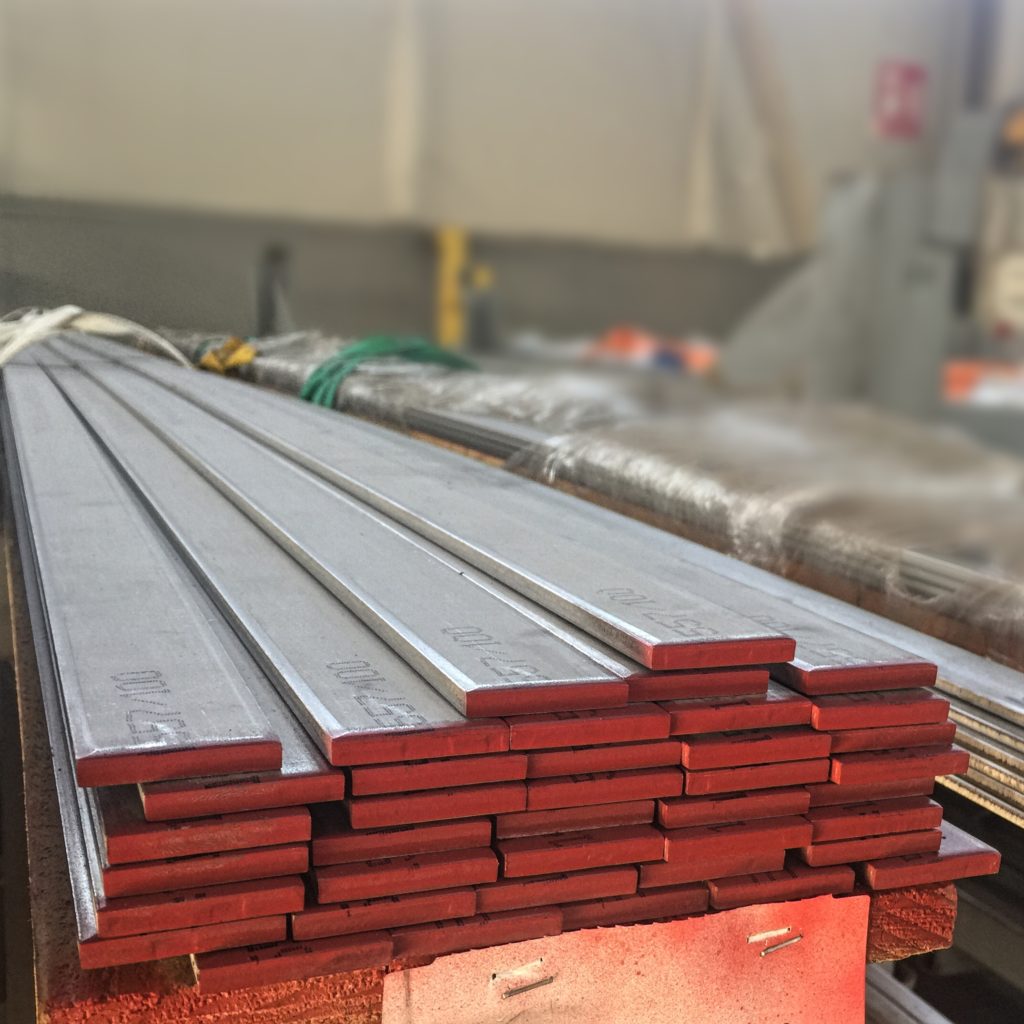

FLAT BARS.

Stainless steel flat bars find many uses and because of this need they differ greatly in their finish and precision.

The categories can thus be split into 3.

The stainless steel sheared flat bar is the best-selling product in the category. It is obtained by shearing through strip/coil slitters and subsequent straightening. It has a slightly flattened/rounded edge caused by the pressure of the rollers cutting it.

The sheared plate is generally supplied in 4 m or 6 m bars but can be customised.

The stainless-steel laminated plate is obtained by the hot rolling process in special machinery, has a slightly rounded edge and wide dimensional tolerances.

The rolled plate is supplied in bars of variable length from 4.5 to 6.5 m.

The cold drawn stainless-steel plate is obtained from the hot rolled plate. After a cold-drawing process, a smooth finish with much tighter dimensional tolerances is obtained. The edge of the drawn plate is well defined (sharp edge) and the length in which it is generally supplied varies from 3 to 4.5/5 metres.

All plates are generally produced in AISI 304 and AISI 316 stainless steels.

ANGULAR BARS.

ROLLED ANGLE BARS

BARS L=6MT

Stainless steel angle bars are mainly used within structures. They have a hot surface finish (porous aluminium colour) and are generated by means of special rolling mills. They can be with equal sides (wings) or not, the inner edge is always rounded while the outer edge has a right angle.

Angle bars are commercially supplied in 6 m rods and produced in AISI 304 and 316 stainless steel.

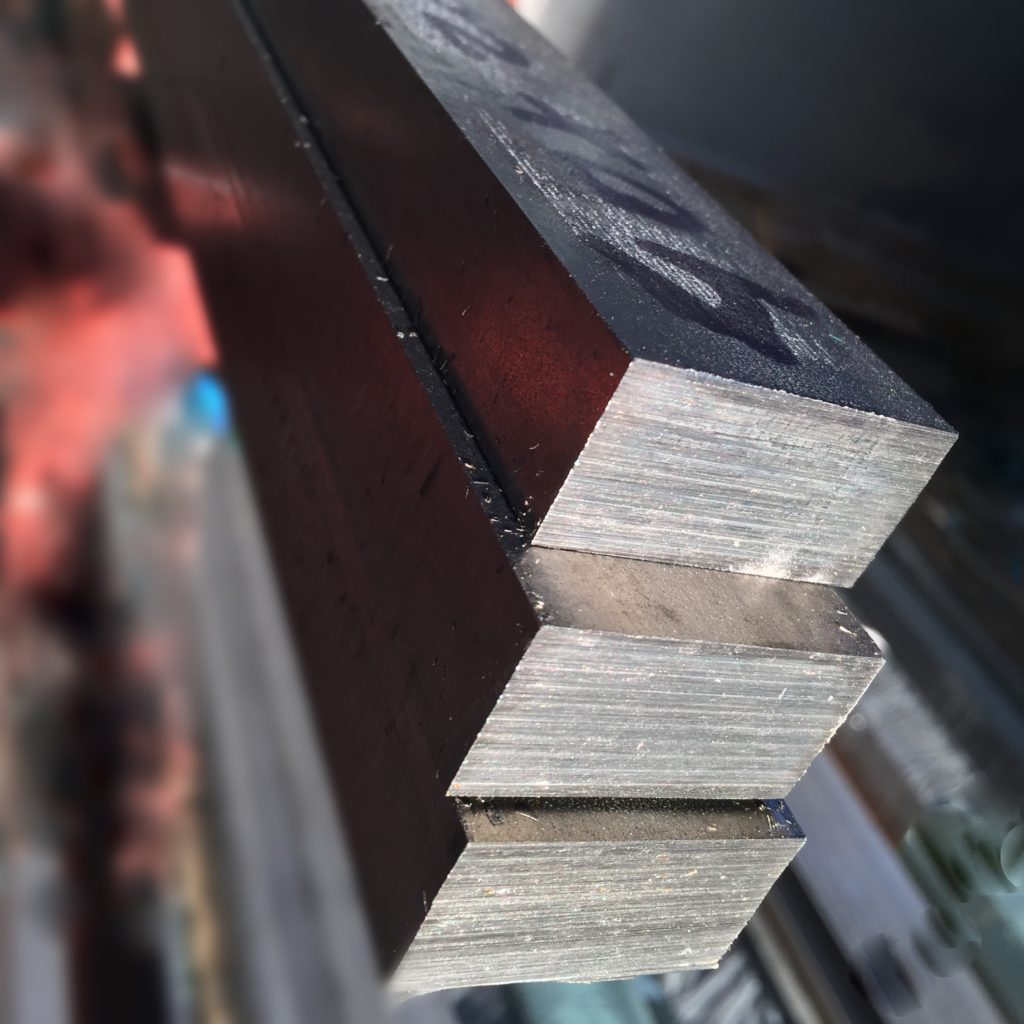

SQUARES.

Stainless steel square bars (stainless square) are most used in mechanical engineering and construction.

They are differentiated into 2 categories according to surface finish.

The cold drawn stainless-steel square is sold in bars of length generally 3mt (in some cases 4mt or 6mt) with the possibility of lengths according to the customer’s specifications, it is widely used in smaller sizes.

The main characteristic is the very tight dimensional tolerance and a sharp edge generated in the production process through cold drawing.

The stainless steel hot rolled square is also sold in bars with lengths varying from 4.5 m to 6.5 m or, depending on demand, in saw-cut pieces.

The dimensional tolerance is wider, the surface finish is rough (aluminium colour) and the edges are slightly rounded.

All stainless-steel boards are sold in AISI 304, AISI 316 steel.

SQUARE BARS

LAMINATED OR DRAWN

HEXAGONAL.

HEXAGONAL BARS

DRAWN

Stainless steel hexagonal bars (stainless steel hexagons) are most used in mechanics and for fasteners.

The stainless hexagon is available in bars generally 3m long (in some cases 4m or 6m) or customized lengths.

The main characteristic is the very tight dimensional tolerance and a sharp edge generated in the production process through cold drawing.

All stainless-steel square bars are sold in the form of AISI 304, AISI 303, AISI 316.

TOLERANCES.

| DRAWING TOLERANCES DIAM/ISO SYSTEM | h7 | h8 | h9 | k11 |

|---|---|---|---|---|

| 1-3 mm | 0/-10 | 0/-14 | 0/-25 | +60/0 |

| 3-6 mm | 0/-12 | 0/-18 | 0/-30 | +75/0 |

| 6-10 mm | 0/-15 | 0/-22 | 0/-36 | +90/0 |

| 10-18 mm | 0/-18 | 0/-27 | 0/-43 | +110/0 |

| 18-30 mm | 0/-21 | 0/-33 | 0/-52 | +130/0 |

| 30-50 mm | 0/-25 | 0/-39 | 0/-62 | +160/0 |

| 50-80 mm | 0/-30 | 0/-46 | 0/-74 | +190/0 |

| 80-120 mm | 0/-35 | 0/-54 | 0/-87 | +220/0 |

| 120-180 mm | 0/-40 | 0/-63 | 0/-100 | +250/0 |